Tissue

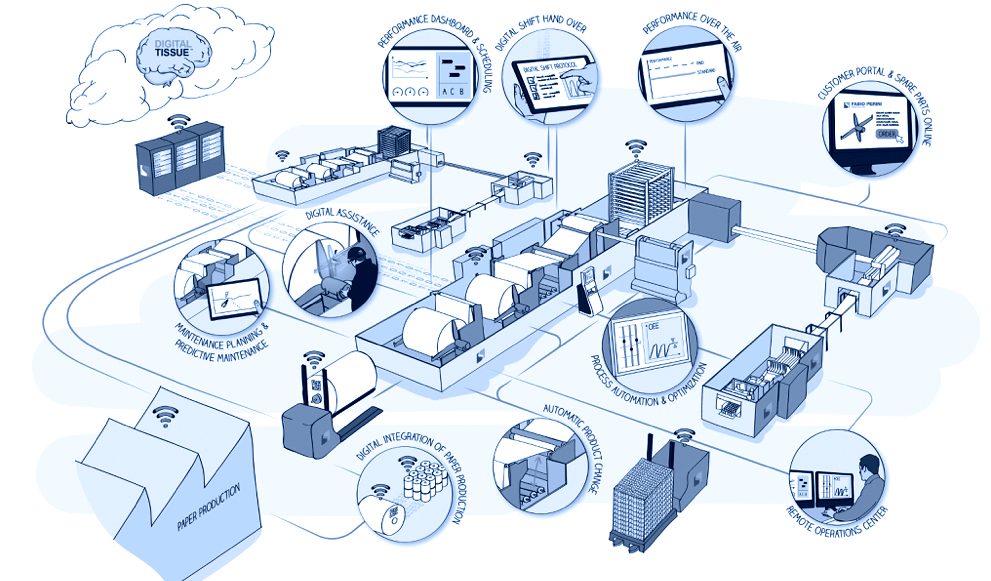

An important aspect of tissue paper products that is sometimes overlooked is the advanced science and technology used to make them. Tissue products are not simple commodities, but instead are high-tech paper specialties based on complex science. To make a tissue sheet, weighing sometimes as little as 13 grams per square meter, with softness, strength and absorbency engineered into the products, is no simple task.

Tissue is made on the paper machine in large jumbo rolls which can weigh up to several tons. These are then transformed in the converting process from very large reels into finished products such as rolls of bathroom tissue or kitchen paper towels, as well as folded products like facial tissue, handkerchiefs and napkins. Advanced high-speed machines carry out the complex winding, cutting, slitting, printing and embossing steps while retaining the functional properties such as softness, strength and absorbency.

Finally, these products are wrapped and packaged into the format needed for stocking in a supermarket or other distribution center before going to the final consumer.

No Comments

Sorry, the comment form is closed at this time.